Here’s a guide to the intricacies of tuckpointing, exploring its techniques, tools, and applications for effective brick repair.

Understanding Tuck Pointing

Tuck pointing, also known as pointing or re-pointing, is the process of renewing the mortar joints between bricks or stone masonry. The technique involves removing deteriorated mortar and replacing it with fresh mortar, restoring the structural integrity and visual appeal of the masonry. Tuck pointing not only addresses aesthetic concerns by enhancing the appearance of brickwork but also reinforces the stability and weather resistance of the structure.

The Importance of Tuck Pointing

Brick structures are exposed to various environmental factors such as moisture, temperature fluctuations, and seismic activity, all of which contribute to mortar deterioration over time. Cracked or degraded mortar joints compromise the integrity of the entire masonry assembly, leading to water infiltration, structural instability, and potential safety hazards. Tuck pointing serves as a proactive measure to mitigate these issues, preserving the longevity and functionality of brickwork.

Techniques of Tuck Pointing

Preparation

Begin by assessing the condition of the existing mortar joints. Use a chisel, grinder, or mortar removal tool to carefully remove deteriorated mortar to a uniform depth, typically around ¾ of an inch. Take caution to avoid damaging the surrounding bricks during this process.

Cleaning

Thoroughly clean the joint cavity and surrounding brick surfaces to remove debris, dust, and loose mortar residue. A wire brush, compressed air, or water jet can be used to achieve optimal cleanliness, ensuring proper adhesion of the new mortar.

Mixing Mortar

Prepare the mortar mixture according to the specifications of the project, considering factors such as mortar type, color, and consistency. Typically, a blend of Portland cement, hydrated lime, and sand is used, with water added gradually to achieve a workable consistency.

Application

Using a pointing trowel or mortar bag, carefully fill the cleaned joint cavity with the freshly mixed mortar, ensuring complete coverage and consolidation. Press the mortar firmly into the joint to achieve a tight seal and uniform appearance.

Finishing

Once the mortar has begun to set but is still workable, use a jointing tool or striking iron to create a neat, concave profile along the joint surface. This not only enhances the aesthetic appeal but also improves weather resistance by directing water away from the joint.

Curing

Allow the newly applied mortar to cure gradually, protecting it from excessive moisture and temperature extremes during the curing process. Depending on environmental conditions and mortar composition, curing times may vary but typically range from 24 to 72 hours.

Cleaning Up

Finally, clean any excess mortar residue from the brick surfaces using a stiff brush or damp sponge before it fully hardens. Proper cleanup ensures a professional finish and prevents unsightly stains on the brickwork.

Tools Required for Tuck Pointing

Tuck pointing demands a precise set of tools to achieve optimal results. Here's a rundown of the essential tools needed for tuck pointing.

Chisel or Grinder

A chisel or grinder serves as the primary tool for removing deteriorated mortar joints. The choice between these tools depends on the scale of the project and personal preference. While chisels offer precision and control for smaller repairs, grinders excel in tackling larger areas quickly and efficiently.

Mortar Removal Tool

This specialized tool provides the precision and control required for accurate mortar removal. Featuring a narrow blade or bit, it allows craftsmen to target specific areas without damaging the surrounding bricks.

Wire Brush

An indispensable tool for tuck pointing, the wire brush is used to clean joint cavities and brick surfaces before applying fresh mortar. Its stiff bristles effectively remove debris, dust, and old mortar residue, ensuring optimal adhesion of the new mortar.

Pointing Trowel

The pointing trowel plays a pivotal role in the tuck pointing process, facilitating the application and shaping of fresh mortar. Its narrow, pointed blade allows craftsmen to work the mortar into the joint cavity with precision, achieving a uniform and aesthetically pleasing finish.

Mortar Bag

A mortar bag provides a controlled method for dispensing mortar into joints, offering greater accuracy and efficiency compared to traditional methods. Craftsmen can easily regulate the flow of mortar, minimizing waste and achieving consistent results.

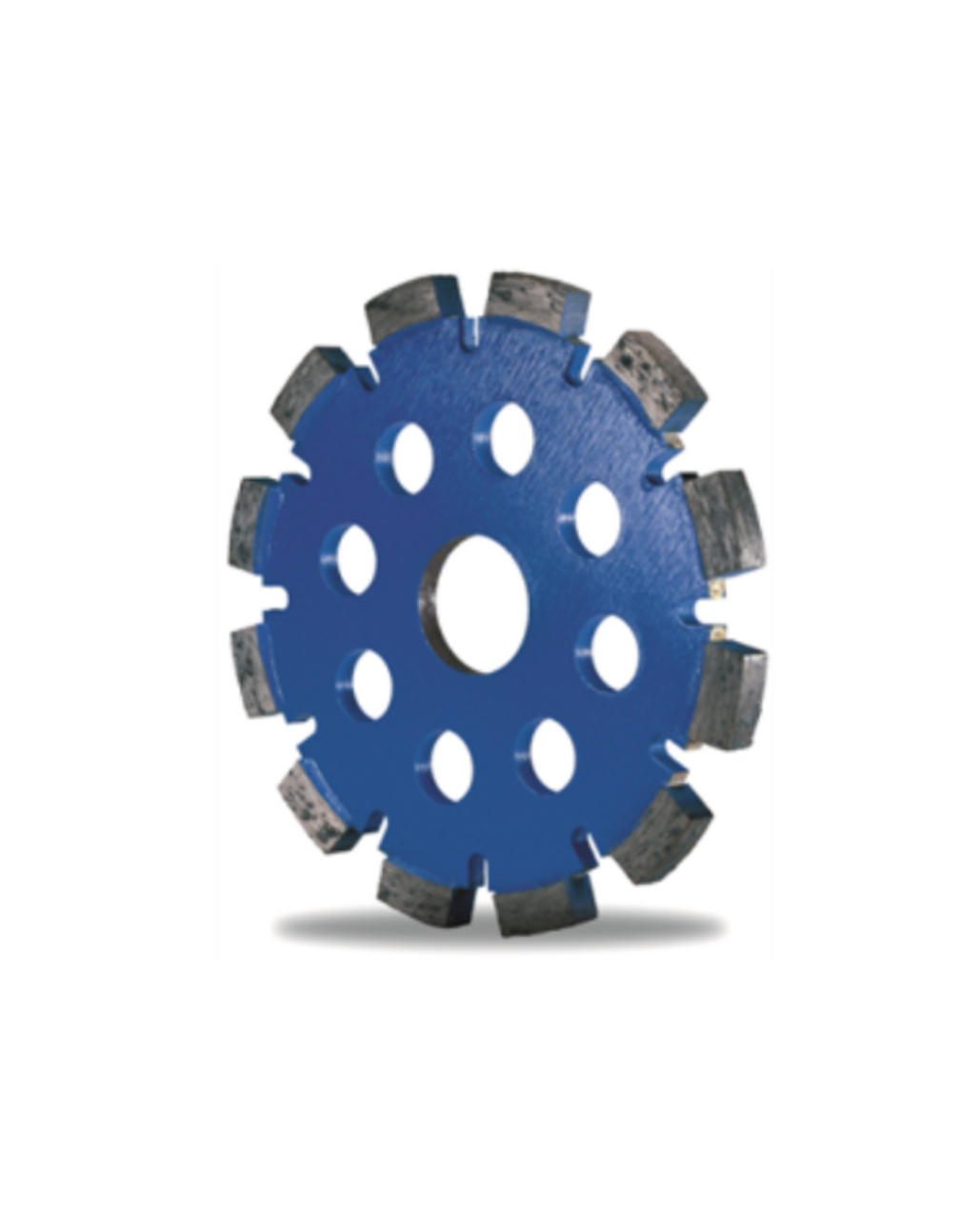

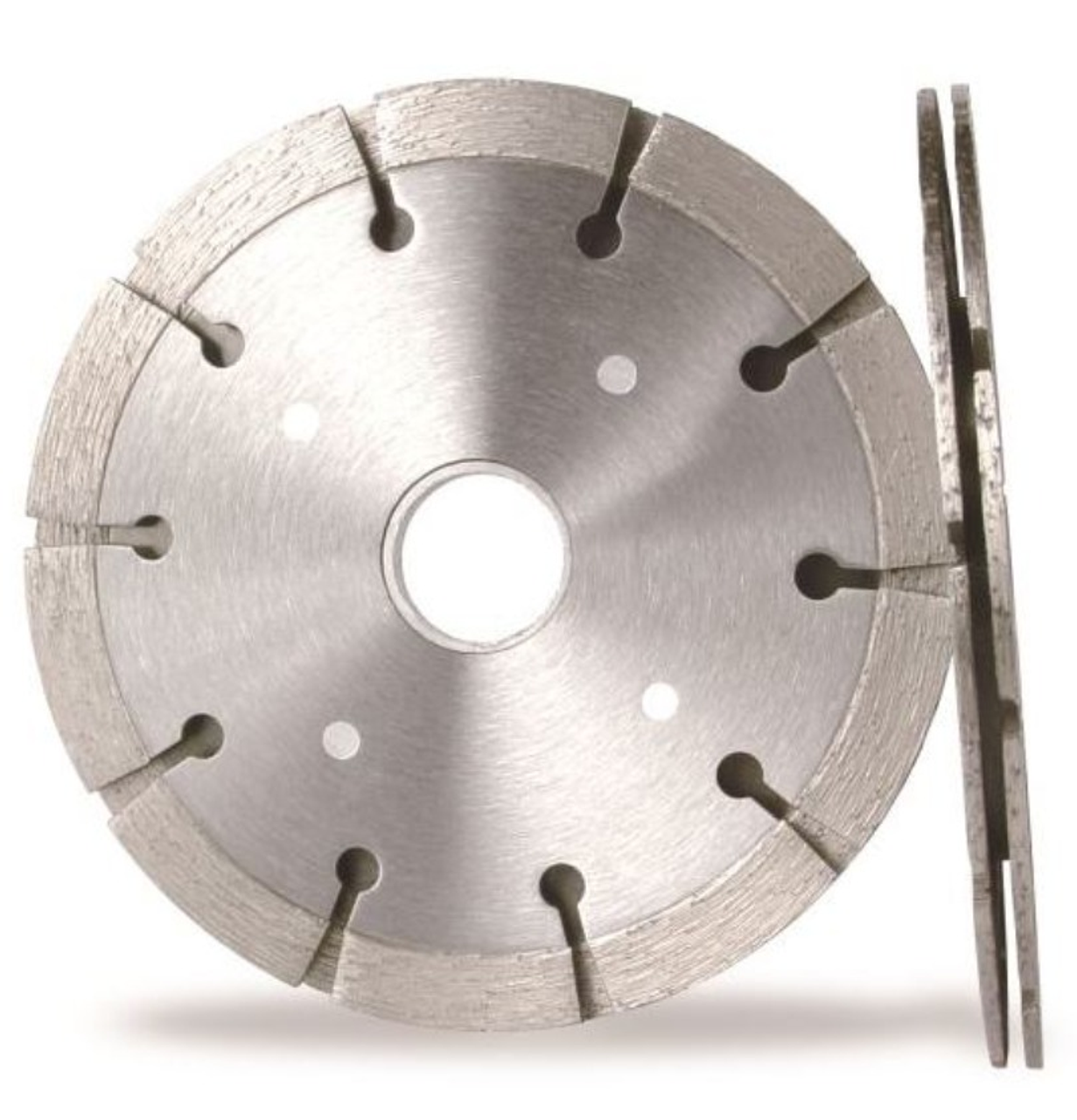

Diamond Tuck Point Blade

Adding a diamond tuck point blade to your toolkit allows for efficient and precise mortar removal, especially in cases where grinders are utilized. The diamond-tipped blade ensures durability and effectiveness in removing old mortar, making it an essential tool for professional tuck pointing projects.

Jointing Tool or Striking Iron

Used for finishing and profiling mortar joints, the jointing tool or striking iron helps achieve a neat and uniform appearance. By creating a concave profile along the joint surface, this tool enhances the aesthetics and weather resistance of the masonry.

Protective Gear

Personal protection is essential during tuck pointing to safeguard against potential hazards such as flying debris and harmful dust. Safety glasses, gloves, and a dust mask are essential protective gear that should be worn at all times during the tuck pointing process.

As you start your tuck pointing project, ensure success with the right tuck pointing tools. At TMS Equip, we offer a comprehensive range, from diamond tuck point grinder blades to diamond masonry blades and more, tailored for diverse projects. Our high-quality blades guarantee precise mortar joint restoration and enduring structures. But TMS Equip doesn't stop there; we also provide essential equipment like dewatering pumps, poly drum concrete mixers, and vibratory plate compactors to support your entire construction project.

Reach out to us for top-notch tuck pointing tools and equipment, elevating the quality and efficiency of your projects.