This blog explores the differences between these methods, focusing on the advantages of each and providing guidance on selecting the right approach for different materials:

The Essentials of Wet Cutting

Wet cutting is a process where water is used as a coolant to reduce dust, decrease heat from friction, and enhance the cutting quality of diamond blades. This method is particularly beneficial when working with materials that generate a significant amount of dust, such as diamond blades for tile and stone. Wet cutting not only helps maintain the integrity of the blade by preventing overheating but also minimizes the risk of airborne silica particles, which can be harmful to breathe.

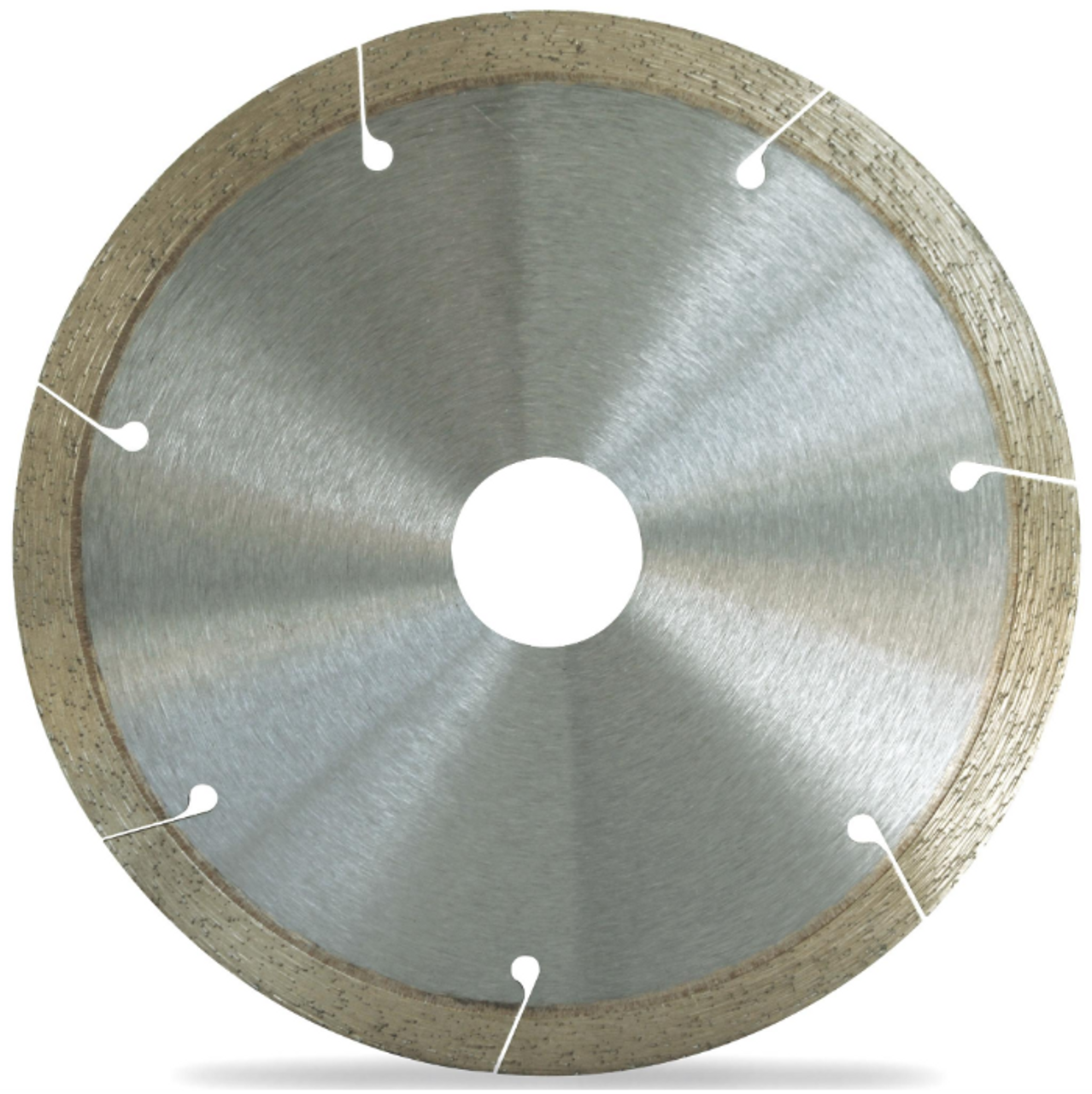

Our continuous rim blades are specifically designed for wet cutting, making them perfect for projects involving ceramic and porcelain tiles. The presence of water during the cut ensures a cleaner and more precise cut, which is ideal for delicate tile work in bathrooms and kitchens.

The Role of Dry Cutting

Dry cutting, on the other hand, does not involve water and is typically used for quick jobs or in situations where water use is impractical. Diamond masonry blades for circular saws are often used in dry cutting to slice through materials like concrete and masonry quickly. Although this method produces more dust and noise, it allows for greater mobility as it eliminates the need for a water source.

When using dry-cutting techniques, it’s important to choose blades like the diamond masonry blade that are designed to withstand the higher temperatures generated by friction. Additionally, implementing adequate dust suppression measures, such as dust extractors or respirators, is crucial to maintain safety.

Choosing Between Wet and Dry Cutting

When selecting the optimal cutting method for any project, several factors must be considered. The choice between wet and dry cutting with diamond blades hinges on material characteristics, job requirements, and site conditions. Both methods have their distinct advantages and challenges, and understanding these can greatly influence the outcome and efficiency of your cutting tasks.

Material Considerations

Different materials react differently under the stress of cutting. Wet cutting is particularly advantageous when working with brittle materials such as ceramic, porcelain, and some types of stone. The water used in wet cutting acts as a lubricant and coolant, minimizing dust and reducing the thermal stress that can cause cracking and chipping. For instance, using a diamond blade for tile in a wet-cutting setup can significantly improve the quality of the cut and extend the life of the blade.

On the other hand, dry cutting is preferred for harder materials like concrete and masonry. These materials require a more robust approach, which dry cutting provides. Blades like diamond masonry blades for angle grinders or circular saw diamond masonry blades are engineered to withstand the intense friction and heat generated during dry cutting. They are also designed to cope with the abrasive nature of such materials, which can wear down blades more quickly if not properly suited.

Job Requirements

The specifics of the job at hand can also dictate the choice of cutting method. For precision jobs that require clean and precise cuts, such as intricate tile work in kitchens and bathrooms, wet cutting is often indispensable. The cooling effect of water helps produce a smooth, fine finish that is aesthetically pleasing and structurally sound.

Conversely, for jobs that need to be completed quickly or where setup and cleanup need to be minimized, dry cutting is advantageous. This method allows for immediate work without the setup of a water source and is ideal for environments where water use is restricted or impractical. Additionally, dry cutting is beneficial when working in indoor environments where water could cause damage or create additional hazards.

Environmental Considerations

Environmental factors also play a critical role in deciding whether to use wet or dry cutting. Wet cutting is environmentally friendly as it suppresses dust and keeps the air cleaner. This method is essential in enclosed or poorly ventilated spaces where dust can pose significant health risks. It also prevents the widespread dispersal of silica dust, which is a serious health hazard associated with cutting materials like concrete.

Dry cutting, while more prone to dust creation, is often necessary in areas where water conservation is a priority or where drainage issues may arise. In such cases, using dust suppression equipment or personal protective equipment can mitigate health risks.

Equipment and Blade Selection

Choosing the right equipment is as crucial as selecting the cutting method. For wet cutting, ensure that the tools and equipment are compatible with wet environments to avoid electrical hazards. Tools and extension cords should be appropriately rated for wet use, and GFCI (Ground Fault Circuit Interrupter) protection is a must.

For dry cutting, the emphasis should be on high-performance blades, such as 14 inch asphalt diamond blades that are capable of handling heat and friction. The choice of blade should align with the material's hardness and abrasiveness to maximize efficiency and blade life.

Safety Considerations and Best Practices

Regardless of the cutting method chosen, safety should always be a top priority. When wet cutting, ensure that the electrical tools used are suitable for wet environments to prevent electrical hazards. For dry cutting, always wear protective gear to guard against dust and debris.

Whether you opt for wet or dry cutting, selecting the right diamond blade for the job is essential for achieving optimal results. By understanding the specific needs of your project and the materials involved, you can choose the most effective and efficient cutting method.

Upgrade Today with TMS Equip!

Upgrade your cutting tools with TMS Equip’stop-quality diamond blades for tile and stone. Perfect for both professionals and DIY enthusiasts, these blades offer unmatched precision and durability.

Contact us now to elevate your cutting efficiency to the next level!