This blog discusses the significance of tuck point blades in masonry work, from grout removal to restoration.

Understanding Masonry Restoration

Masonry restoration is the process of repairing and preserving historic or aging structures made of brick, stone, or concrete. Over time, factors such as weathering, pollution, and structural movement can cause damage to masonry surfaces, including mortar deterioration and cracks in bricks or stones. Restoration aims to address these issues while maintaining the architectural integrity of the structure.

The Role of Grout Removal

Grout, the mortar used to fill gaps between bricks or stones, deteriorates over time due to exposure to the elements. As part of the restoration process, damaged or deteriorated grout must be removed to allow for proper repair and replacement. Grout removal is a meticulous task that requires precision tools to avoid damaging surrounding masonry elements.

Enter the Tuck Point Blade

Tuck pointing is a technique used in masonry restoration to replace deteriorated mortar joints with fresh mortar. Tuck point blades are specialized tools designed for this purpose. These blades feature a narrow profile with diamond or abrasive segments specifically engineered for grout removal and precision cutting.

Key Features of Tuck Point Blades

Diamond or Abrasive Segments

Tuck point blades come in various configurations, including diamond or abrasive segments. Diamond blades are ideal for cutting hard materials such as concrete and stone, while abrasive blades are suitable for softer materials like mortar.

Narrow Profile

The narrow profile of tuck point blades allows for precise cutting in tight spaces, such as between bricks or stones. This feature is essential for maintaining the aesthetics of the masonry structure during restoration.

Thickness Options

Tuck point blades are available in different thicknesses to accommodate various grout joint widths. Choosing the appropriate thickness ensures the proper removal of deteriorated grout without causing damage to surrounding masonry elements.

Heat Dissipation

Tuck point blades are often designed with special features to dissipate heat generated during cutting. This helps prevent overheating of the blade, which can lead to premature wear and reduced cutting efficiency. Heat dissipation features may include laser-cut cooling vents or specially formulated blade materials that minimize friction and heat buildup.

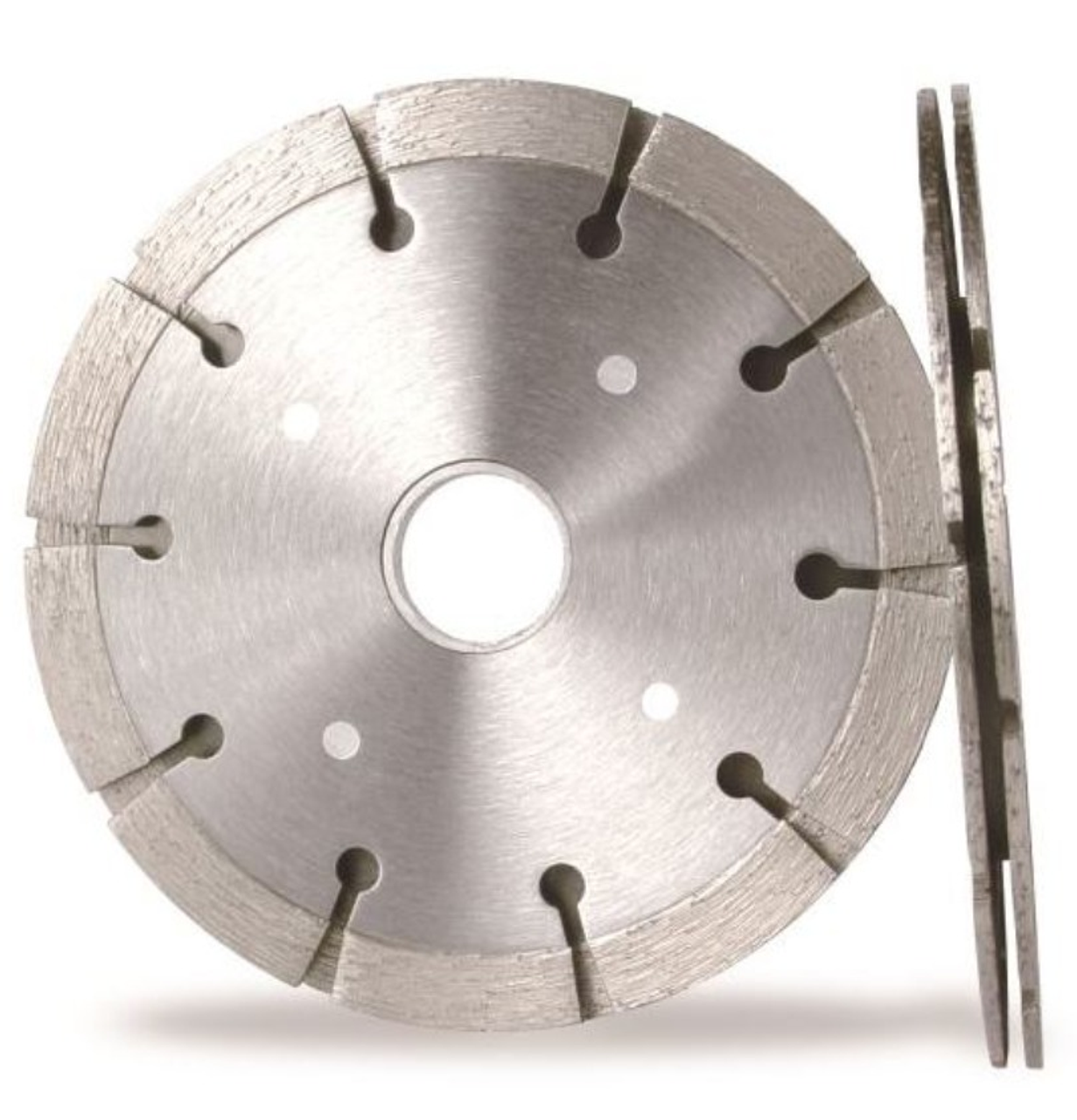

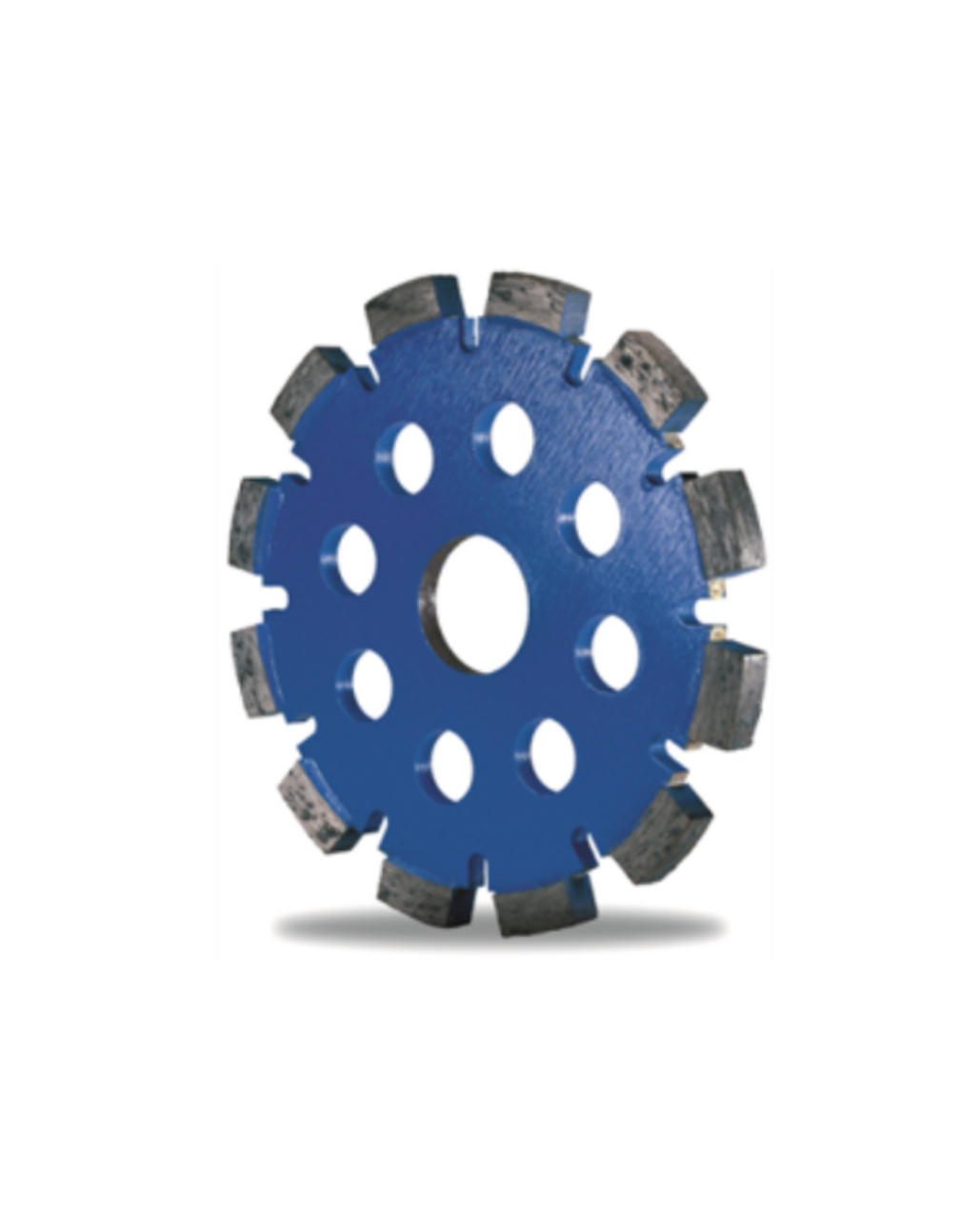

Segmented Design

Many tuck point blades feature a segmented design, with individual segments separated by narrow slots or gullets. This design helps improve the blade's cutting performance by allowing for efficient debris removal and cooling during operation. Segmented blades also provide added flexibility, making them suitable for both wet and dry cutting applications.

Compatibility with Different Materials

Tuck point blades are available in a variety of configurations to accommodate different masonry materials and applications. Some blades are specifically designed for cutting softer materials like brick and limestone, while others are optimized for harder materials such as concrete and granite. Choosing the right blade for the job ensures optimal cutting performance and longevity.

Arbor Size Options

Tuck point blades come with a range of arbor sizes to fit different power tools and equipment, including angle grinders and circular saws. Standard arbor sizes include 5/8-inch, 7/8-inch, and 1-inch, among others. Selecting the correct arbor size ensures compatibility with the user's equipment, allowing for seamless integration and efficient operation.

Longevity and Durability

High-quality tuck point blades are engineered for long-lasting durability, allowing them to withstand the rigors of masonry restoration work. These blades are constructed from premium materials such as industrial-grade diamonds or abrasives bonded to a robust steel core. Additionally, advanced manufacturing techniques and quality control processes ensure consistent performance and extended blade life, reducing the need for frequent replacements and lowering overall project costs.

Applications of Tuck Point Blades

Grout Removal

Tuck point blades excel in removing deteriorated grout from mortar joints without damaging adjacent bricks or stones. The precision cutting ability of these blades allows for accurate removal of old mortar, preparing the surface for tuck-pointing.

Tuck Pointing

Once the old mortar has been removed, tuck-point blades are used to create clean, uniform grooves in the mortar joints. This process prepares the joints for the application of fresh mortar, enhancing both the structural integrity and aesthetic appeal of the masonry work.

Crack Repair

In addition to grout removal and tuckpointing, tuck-point blades can also be used to cut and prepare cracks in bricks or stones for repair. By removing damaged sections of masonry, these blades facilitate the application of repair materials, restoring the structural integrity of the affected area.

Best Practices for Using Tuck Point Blades

Safety First

When working with tuck point blades, always wear appropriate personal protective equipment, including safety glasses, gloves, and respiratory protection. Follow manufacturer guidelines and recommendations for the safe operation of the equipment.

Proper Technique

Use a steady hand and gentle pressure when operating tuck point blades to avoid damaging surrounding masonry elements. Start with a shallow cut and gradually increase the depth as needed, taking care not to overcut or undercut the mortar joints.

Regular Maintenance

Keep tuck point blades clean and free from debris to maintain optimal performance. After each use, inspect the blades for signs of wear or damage, and replace them as necessary to ensure consistent results.

diamond-tuck-point-grinder-blade-white

For high-quality tuck point blades for masonry and a wide selection of other premium masonry tools and equipment, opt for TMS Equip. Our collection includes diamond tuck point grinder blades, diamond masonry blades, crack chaser blades, asphalt saw blades, field stone cutting blades, and more, catering to all types of projects and applications. We also have dewatering pumps, vibrating plate compactors, compaction rammers, and other machinery and replacement parts available for quick delivery.

Contact us today to explore our extensive range of products and take your masonry restoration projects to the next level.