Advanced Innovations in Diamond Blade Technology

The diamond blade industry is witnessing numerous technological advancements that are transforming cutting applications across various materials. These innovations not only enhance performance but also prioritize sustainability and user comfort.

Laser-Welded Diamond Segments for Enhanced Durability

Laser-welded diamond segments are a crucial development, providing stronger bonds between the diamonds and the blade core. This technique significantly increases the durability of the blades, making them ideal for cutting tougher materials like concrete and asphalt.

Cooling Holes for Efficient Heat Management

Incorporating cooling holes in diamond blades is an innovation designed to mitigate heat build-up during cutting processes. These holes help prevent the blade from warping and losing its cutting efficiency, thereby extending the life of the blade.

Noise Reduction for Comfortable Environments

The introduction of noise-reduction technology in diamond blades addresses noise concerns in work environments. Blades equipped with vibration-dampening cores reduce noise output significantly, making operations less disruptive in noise-sensitive areas.

Anti-Vibration Features for Precision Cuts

Anti-vibration technology is another important advancement. By stabilizing the blade during operation, this technology minimizes vibrations that can lead to user fatigue and imprecise cuts, ensuring smoother and more controlled cutting.

Optimized Diamond Matrix for Faster Cutting

Enhancements in the diamond matrix of these blades allow for a more efficient distribution of diamond particles, which accelerates the cutting process without compromising cut quality. This improvement is essential for professionals needing quick and reliable results.

Tailored Segment Designs for Specific Materials

Custom segment designs are developed to address the unique challenges posed by different materials. For example, blades designed for cutting asphalt may have segments that efficiently clear away debris, while those intended for masonry might focus on precision and minimal brick damage.

Eco-Friendly Manufacturing Practices

The shift towards eco-friendly manufacturing practices reflects a growing awareness of environmental impact in the diamond blade industry. Efforts to recycle used blades and reduce production waste are steps towards more sustainable manufacturing processes.

Variable Diamond Grit Sizes for Enhanced Versatility

Innovations in diamond grit technology have led to the development of blades with variable grit sizes. This adaptation allows for blades to be customized for specific materials, ensuring optimal cutting performance. Coarser grits are ideal for rapid material removal and cutting softer materials, while finer grits are suited for achieving a smooth finish on hard materials.

Improved Bonding Techniques

Advancements in the bonding materials that hold the diamond particles in place have significantly improved the performance of diamond blades. These new bonding techniques ensure that the diamonds remain attached longer, allowing for extended use of the blade and reducing the frequency of blade replacements.

Segment Configuration for Optimal Debris Removal

Segment configuration has also seen innovative changes. The layout and design of the segments can now enhance the removal of debris from the cut, which is critical in maintaining cutting speed and preventing overheating. This is particularly beneficial when cutting materials that generate a lot of particulate matter, such as concrete or stonework.

Smart Blades with Wear Indicators

The introduction of "smart" diamond blades equipped with wear indicators is a breakthrough in tool management. These indicators provide users with real-time feedback on blade condition, helping to optimize blade usage and prevent damage from overuse. This technology also aids in ensuring that blades are replaced at the right time to maintain peak performance.

Environmentally Conscious Production Processes

As sustainability becomes a greater concern, the industry is focusing on reducing the environmental impact of diamond blade production. This includes the use of recycled materials in the blade manufacturing process and the implementation of production methods that minimize waste and energy consumption.

Safety Features and Ergonomic Design

Safety remains a paramount concern in the design of diamond blades. Modern blades are now being equipped with features that reduce the likelihood of blade kickback and other common hazards. Additionally, ergonomic considerations are being incorporated to make tools easier and safer to handle, reducing the risk of injury and fatigue for the user.

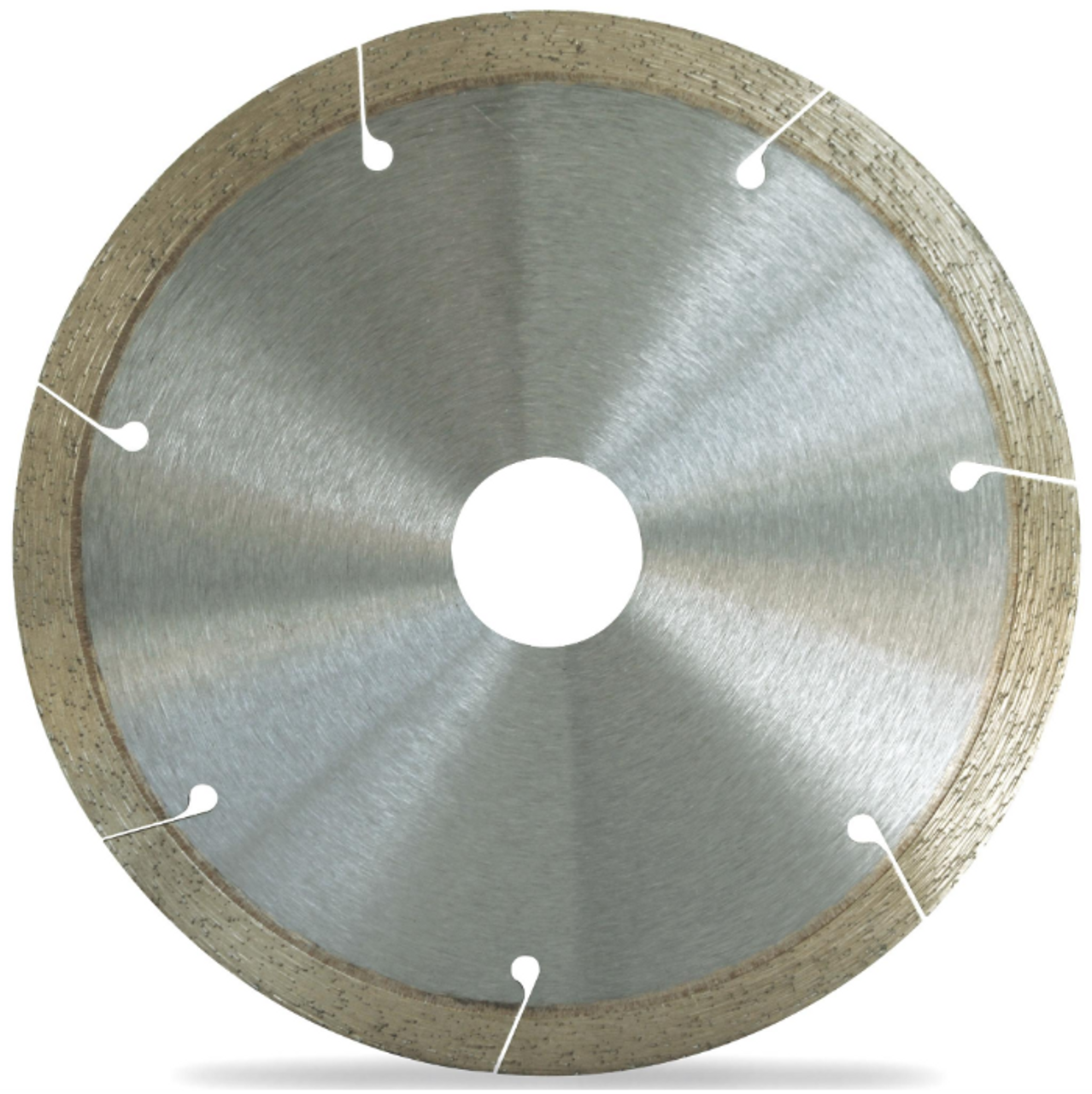

Cutting-Edge Features of TMS' Tile and Stone Blades

TMS has developed a line of premium diamond blade for stone that are revolutionizing the industry. Designed specifically for wet cutting applications, these continuous rim blades excel in delivering precise cuts for both ceramic and porcelain tiles. Ideal for projects such as bathroom renovations or kitchen backsplashes, these blades ensure clean, chip-free cuts that are essential for high-quality finishes.

Unmatched Precision and Versatility

The versatility of TMS' diamond blades is where they truly shine. Not limited to just tiles, these blades are also capable of handling various stone types, including field stone. This adaptability makes TMS blades invaluable to both professionals and DIY enthusiasts who face a range of materials and challenges in their projects. Their advanced design allows for effortless transitions between different materials, ensuring smooth and efficient cutting across the board.

Durability Meets Professional Grade Standards

TMS blades are not just about precision but also durability. These blades were constructed to withstand the rigors of intense cutting tasks and maintain their performance over time, making them a cost-effective choice for continuous use. Whether it’s a diamond masonry blade for an angle grinder or a circular saw diamond masonry blade, TMS offers solutions that sustain their cutting capabilities even under the toughest conditions.

Why Choose TMS Diamond Blades?

When selecting a diamond blade, one must consider both the quality of the cut and the longevity of the blade. TMS' diamond blades, including specialized options like the 4 crack chaser diamond blade and the 14 inch asphalt diamond blade, provide not only precision but also unmatched durability. Investing in a TMS blade means investing in a tool that will deliver superior results time and again.

Get the Best in Cutting Technology

Elevate your project quality with our diamond masonry blade. Ideal for both professional contractors and DIY enthusiasts, our blades offer unmatched precision and durability.

Don't miss out—contact us today to order your specialized tile-cutting blade and take your projects to the next level with TMS!